Custom-Built Power Distribution Center for Oil & Gas Company

Overview

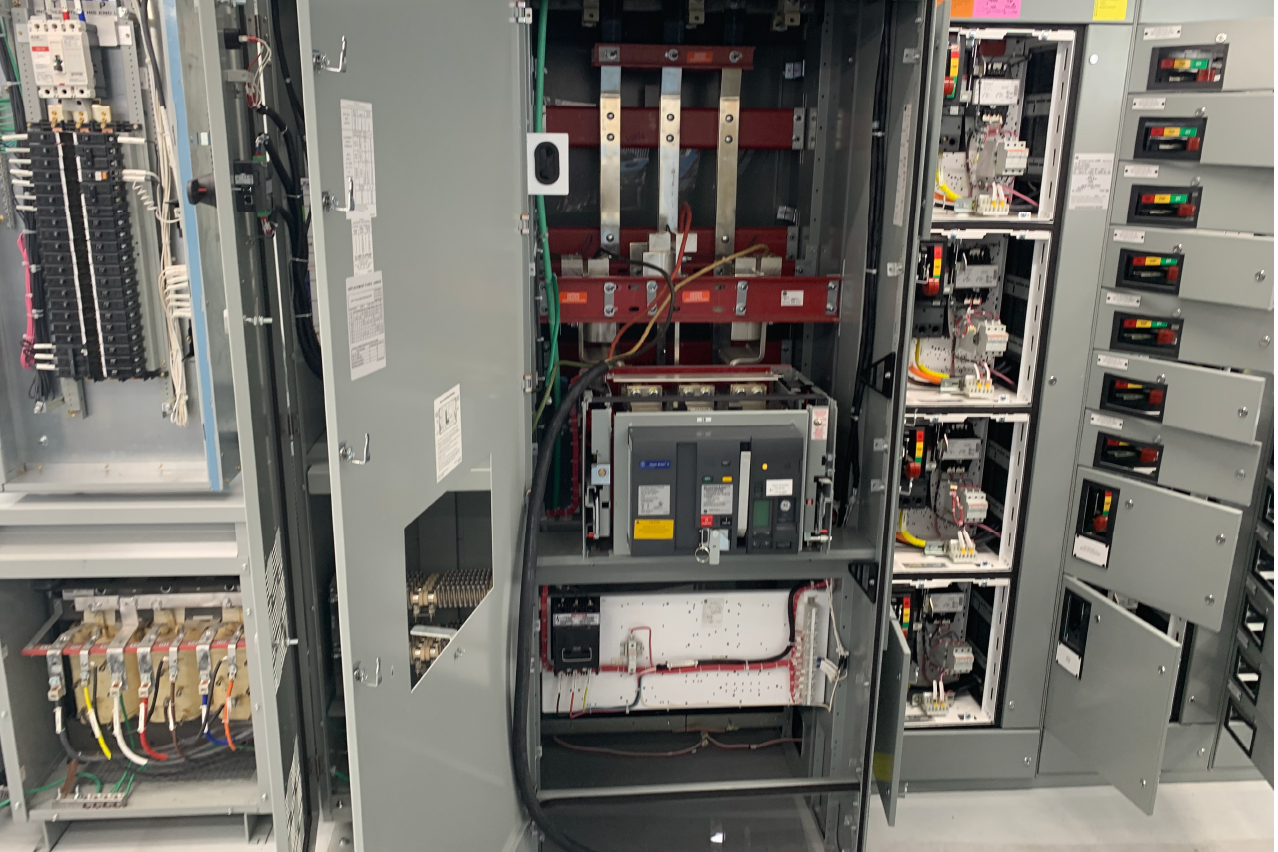

RPS designed and built a custom, prefabricated Power Distribution Center (PDC) to support the power requirements of a pipeline project in the Oil & Gas industry. In addition to fabricating the PDC enclosure shell, the project involved procuring and integrating low and medium-voltage gear and other electrical equipment and transporting it to the job site.

The RPS team was able to:

- Design and deliver a turn-key custom solution based on the customer’s requirements and budget

- Execute from concept to design and through installation

- Executed complex delivery of the Power Distribution Center, navigating challenging delivery restrictions

Challenge

The customer needed a turn-key solution in a short timeframe to meet critical schedule needs on a budget. The site’s terrain, height, and turning radius restrictions were a significant barrier to the prefabricated alternative. A traditional stick-built construction was unsuitable since it could not run parallel to site prep work and could add to costs.

Solution

RPS solved this challenge with prefabricated enclosures. These enclosures minimized field costs and other risks for the customer and allowed them to install, integrate, and test their equipment at the warehouse while the field team worked on-site. Once ready, the field scheduled the delivery with RPS and had a completed building on site soon after. By working on the site and PDC preparation in parallel, the customer could control progress to ensure alignment and success.

RPS overcame the complex delivery restrictions by using swamp mats, jack, and slide techniques and transporting the enclosure on a busy interstate highway. By utilizing a specially designed trailer, RPS delivered the PDC to the site despite its limiting terrain, height, and turning radius restrictions.

- Retrofit Package

- Engineering Design

- Project Management

- Parts Procurement

- Complete Fabrication

- Pre-wiring, Testing, & Pre-Installation

- Complete Integration & Staging

Impact

By working with RPS, the customer could enjoy the schedule and cost benefits of a prefabricated PDC, despite route and site restrictions that would typically required the use of a stick-built construction plan. The RPS team walked the enclosure through the tightest sections of the route to ensure safety of both the customer equipment and surrounding civil infrastructure.