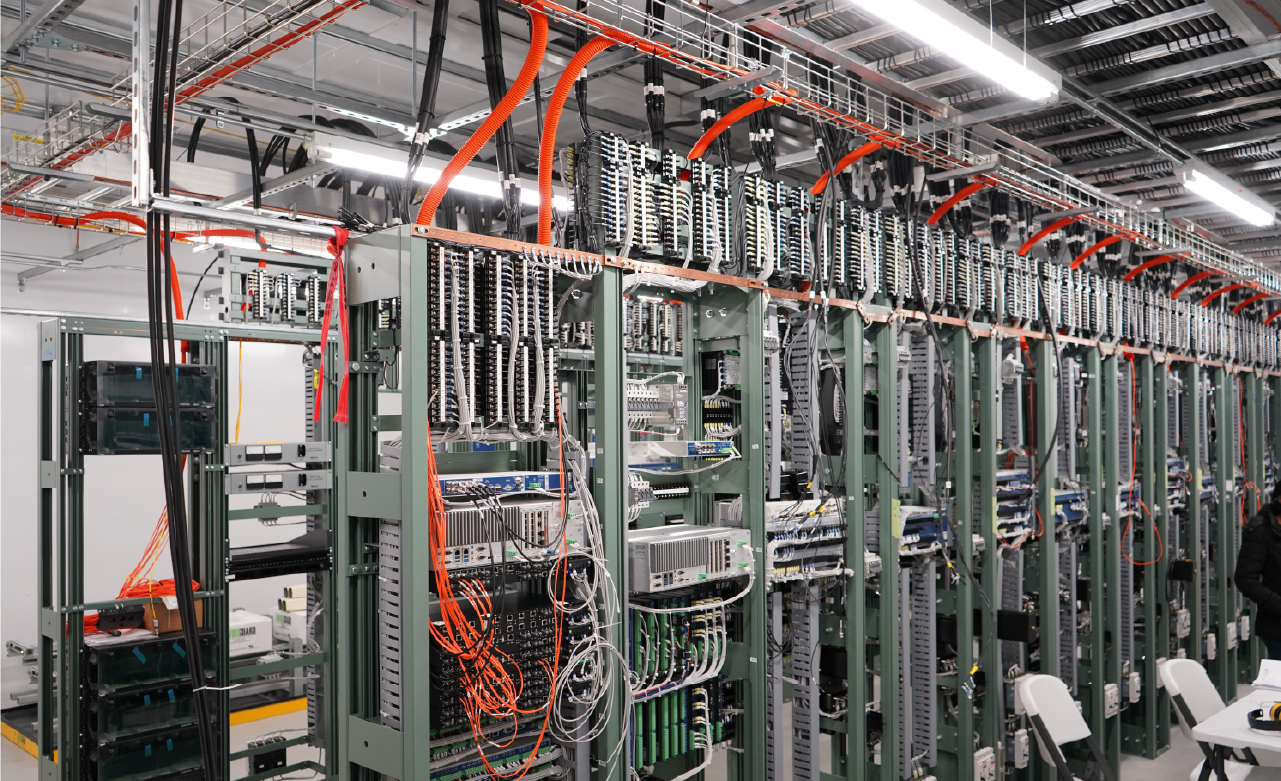

Custom-Built Relay Panels for Local Utility

Overview

An electric utility company was scheduled to upgrade their relay panels to meet increased demand for power, but the upgrade had to be completed within their scheduled outage timeframe. RPS had to build, test, and install the custom panels based on the customer’s requirements within the tight schedule.

The RPS team was able to:

- Design and build relay panels to meet the utility customer’s needs

- Execute from concept to design and through installation

- Install the relay panels to facilitate power supply to customers on schedule

Challenge

The primary challenge RPS faced was meeting the utility’s schedule. The upgrade included over 100 relay panels and 10+ termination panels that had to be built, tested, and finally installed at the customer’s site.

Solution

The RPS team met the customer’s schedule by expeditiously building the relay panels in their fully equipped panel shop in the USA. The project involved design, build, testing, and installation of the relay panels. Deliverables included building the relay and termination panels, drafting schematic diagrams, detailing wiring layouts, designing building blueprints, and manufacturing various components integral to the project.

- Design and Build of Relay Panels

- Project Management

- Parts Procurement

- Complete Fabrication

- Pre-wiring, Testing, & Pre-Installation

- Complete Integration & Staging

Impact

One of the major goals of this project was to meet the increased demand for power and complete the upgrade during scheduled outages. The panel upgrade was completed on time, on schedule, and on budget. By completing the upgrades during scheduled downtime, RPS ensured the end users faced minimal service disruption. It helped to alleviate scheduling pressure for the utility company and fulfilled their requirement for upgraded panels.